High Quality Book Style Folding Box with Flap Lids for Toner and Lotion

Application Industry: Perfume, Cosmetics, Wine, Watch, Wedding, Jewelry and Fragrance

Material: Coated paper, Kraft Paper, Art Paper, Paperboard, Specialty Paper

Feature: Eco-friendly, Recyclable, Durable, High Quality

Size: 23 x 23 x 6cm

Color: CMYK or Spot color

Handle: Ribbon, Cotton, PP, Nylon Rope

Surface Finish: Spot UV, Matte or Glossy Lamination, Foil Stamping, Embossing, Debossing, Gold or Silver hot stamping

Logo: Customized

OEM Service: Yes

Sample Time: 2-5 days

Sample Fee: 50$ , can be refund after bulk order confirmed

Order delivery time: 15-18 days, depends on quantity

Payment Terms: T/T, L/C(for large value order), Western Union, Paypal

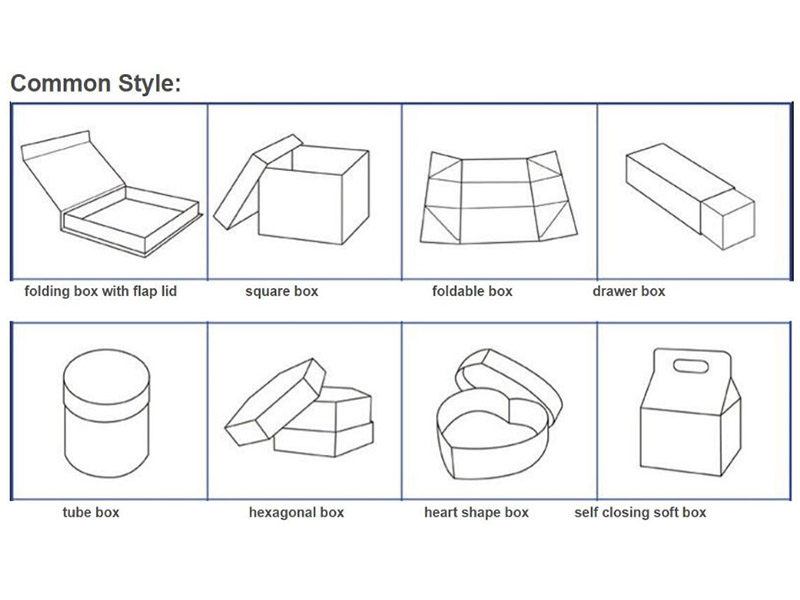

Rigid Box common styles:

Differences between Folding Cartons and Custom Rigid Boxes

Even though both products are used for packaging there are still some differences between them which are described below: Custom rigid boxes and folding cardboard are made from paperboard however, the paperboard used in the manufacturing of rigid boxes is four times thicker than the cardboard. Folding cartons can be collapsed and can still be reassembled in a box whereas, the custom rigid boxes are sturdy and so they can’t be collapsed and reassembled as a box. The printing techniques at folding carton are directly applied while the rigid boxes require another material to be glued to the box for printing. The folding cartons are inexpensive and therefore can be manufactured quickly in bulk in comparison to the rigid boxes. The dies used on folding cartons is expensive in comparison to the ones used at custom rigid boxes.

The process of manufacturing custom rigid boxes at Raymin Display is categorized into five phases. The five stages include material, box style, printing technique, finishing touches and finally extra décor to develop a brand image of your product as luxurious.1. Materials offered at Raymin Display for Custom Rigid Boxes Choose a material that is suitable for your product. The material chosen for the customized rigid boxes should be strong, functional and stylish.